Welcome to Controls Traders, located in Adelaide, South Australia. We are a supplier of quality building automation controls and peripheral products for the HVAC industry. We stock a full range of controllers, sensors, valves and actuators, damper actuators and accessories to suit any application. Our aim is to provide our customers with the highest level of service, from sales to delivery and after sales support. With our extensive in-house knowledge and expertise in the industry, we can advise you on selection and application of our wide range of controls products.

Backed by 40 years industry experience. When you just need to be sure.

No, we’re serious. Anywhere. Anytime.

We stock all major global brands. And if we don’t have it, we’ll find it.

We warehouse the stock so you don’t have to wait.

$150.00 ex GST

Helpful guys over the counter, prompt responses and stock a wide variety of HVAC equipment. One of my go-to stores for parts and advise.

08/10/23

Huge range of HVAC controls readily available off the shelf with excellent customer service and knowledge amongst all staff!? If it's not on the shelf they can get it for you quick!

02/10/23

Great service, great products. The guys are always very helpful and will try to get whatever you need.

19/09/23

Have been using Control Traders for a while now. Peter and the team have been very helpful. Great prompt service

28/10/23

If you're a building automation contractor, HVAC technician, or facilities manager working anywhere across Australia, you've likely run into solenoid valves. You'd typically find them in a chiller system, water supply line, or fuel tank setup. But when it’s time to repair or specify one, questions come up fast:

What is a solenoid valve? How does it work? What do all the configurations even mean?

A solenoid valve is an electrically controlled valve that opens or closes the flow of a liquid or gas in a system. It relies on a solenoid coil (an electric coil) to move an internal plunger that either allows or blocks flow. That’s the basic mechanism, one that powers thousands of fluid and gas control systems around the world.

And it doesn't matter what your automation process is, getting the solenoid valve type and pressure range right is critical for safety, energy efficiency, and uptime.

The core purpose of a solenoid valve is to automate fluid or gas control. Rather than manually turning valves on or off, solenoid valves allow systems to do this on schedule or in response to signals, like a temperature rise or a safety trigger. They’re essential for process control systems, safety shutdowns, precise dosing, and on-demand water or gas control.

Solenoid valves automate the flow of air, water, steam, oil, refrigerant, or inert gases using electrical signals.

Here’s a breakdown of where you’ll find them and why:

Solenoid valves are used to open or close chilled water loops, hot water coils, or DX refrigerant circuits based on system demand or thermostat signals.

In agriculture, solenoid valves automate water delivery in drip irrigation, sprinkler systems, and fertigation setups. These valves respond to controllers, soil sensors, or timers.

Precision dosing, clean media flow, and fast shutoff are vital in medical and laboratory gear.

In manufacturing and workshops, solenoid valves control compressed air lines, often managing energy cycles, actuator movement, or air tool control.

These applications require solenoid valves rated for flammable liquids or gases such as diesel, petrol, LPG, or kerosene.

General-purpose solenoid valves (usually 2/2-way direct acting or pilot operated types) are used where basic open/close control is needed.

Applications include:

First, what is a general-purpose solenoid valve?

A general-purpose solenoid valve is an electromechanically operated valve designed to control the flow of liquids or gases in a wide range of everyday systems. It’s called general-purpose because it’s built for non-specialised, broad applications where there are no extreme operating conditions (like super high pressure, corrosive fluids, or sterile environments).

General-purpose solenoid valves are flexible and cost-effective, typically operating within:

However, they’re not suited for corrosive, high-viscosity, or high-temperature applications without specific materials and certifications.

At its core, a solenoid valve has three elements: a solenoid coil, a plunger, and a valve body. When electrical current energises the coil, the magnetic field lifts or lowers the plunger, which opens or closes the valve seat to control flow.

Let’s break down what that means in practice:

Most solenoid valves are normally closed. That means when there’s no power, the valve blocks flow. Apply power, and the valve opens instantly, simple, fast, and reliable.

Some solenoid valves are directional; they control not just whether fluid flows, but also where it flows. Think of them like traffic controllers in multi-port setups.

By adjusting valve seat size, port configuration, or pressure differential, you can dial in how much fluid moves through the system. Some valves offer flow metering or variable flow options.

Using a solenoid valve with pressure range settings and electronic controllers, you can regulate how quickly fluid flows. That’s useful in dosing applications or when dealing with pressure-sensitive equipment.

Solenoid valves aren’t one-size-fits-all. Their internal architecture determines how they behave, where they’re useful, and how much pressure they can handle. Here are key features to understand:

Dual-coil or multiple-solenoid valves enable bidirectional control or enhanced responsiveness. Useful in complex automation sequences or rapid cycling systems.

Latching solenoids use a brief pulse to change state and then remain in that state, saving power consumption and making them ideal for battery-powered or remote systems.

In Australia, a general-purpose solenoid valve typically ranges from $50 to $300+, depending on size, valve body material (e.g., stainless steel vs brass), seal material, and pressure rating. Custom or high-pressure versions may cost more, especially if special approvals (WRAS, ATEX) are required.

A faulty solenoid valve may get stuck in the open or closed position, cause pressure loss, or trigger inconsistent system behaviour. Common signs include overheating coils, erratic flow, or humming noises. If you ever need a replacement, you can browse stocked solenoid valves from trusted global brands at Controls Traders.

Yes, but it depends on the pressure rating and construction. Pilot-operated valves are generally preferred for high-pressure applications, as they require less coil force. Always check the minimum pressure differential and verify it matches your system’s specs.

Go with direct acting valves when dealing with low pressure or no pressure differential, like in tank drain systems or vacuum lines. Use pilot-operated valves when you have sufficient line pressure and need to handle higher flow volumes.

Whether you’re looking for a normally closed, direct-acting, or pilot-operated solenoid valve for your automation setup, choosing the right type can be challenging. That’s where Controls Traders can help.

We stock right thanks to our over 40 years of combined HVAC and automation expertise. You can browse by product or explore by brand. If you need someone to talk to, call us on 1300 740 140 or send a message and we will get back to you.

Read more

When managing climate control across a commercial building, plant, or healthcare facility, you know every valve, wire, and controller needs to just work. But if you’re a building services engineer, HVAC tech, or facility manager in South Australia, chances are you’ve dealt with unreliable airflow, sluggish valve response, or unclear actuator feedback.

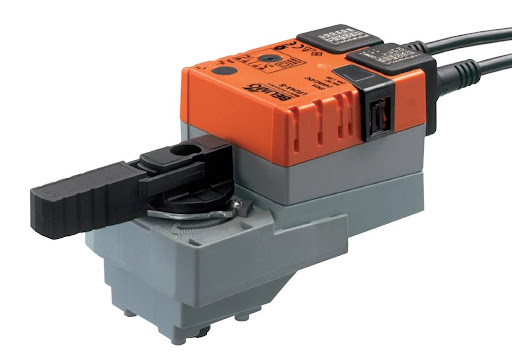

Knowing how a Belimo actuator works is important for precision in a system's performance.

A Belimo actuator uses electric or spring-return motion to precisely open, close, or modulate valves, regulating the flow of air or fluid in your HVAC system automatically. It's the core muscle behind automation, safety, and energy control.

And when you know what’s happening inside the actuator, Hutt.

In simple terms, a Belimo actuator is a device that moves a valve to control the flow of air or water in an HVAC system. It turns electrical signals from your building automation system (BAS) into mechanical motion, opening or closing valves to modulate flow based on temperature, pressure, or occupancy demand.

If your system decides it’s too hot inside and calls for chilled water, the actuator is what physically moves the valve so chilled water can flow through.

That’s the basic function. But Belimo actuators are far from basic in design.

Here’s a simplified breakdown of how these high-performance valve actuators operate:

One standout Belimo feature is its fail-safe function. If there’s a power loss, spring-return or battery backup models automatically return the valve to a safe position ,reducing the risk of overheating, flooding, or system failure.

And for projects chasing sustainability ratings? Belimo’s energy valves combine an actuator, flow sensor, temperature sensors, and logic control to measure, monitor, and modulate energy usage at the coil level. These can help reduce commissioning times and optimise energy use without adding more BAS complexity.

What sets Belimo apart is the engineering behind every actuator. Here’s a breakdown of the features HVAC technicians, facility managers, and controls engineers actually care about:

Belimo rotary actuators deliver torque ranges from 2 Nm to 40 Nm across their standard series, and up to 160 Nm in specialised models, ideal for ball, butterfly, or globe valves up to DN300. Whether you're controlling chilled water loops or high-flow AHU dampers, these actuators are built to move heavy valve bodies without stalling.

Many Belimo models include spring-return or supercapacitor-based fail-safe mechanisms that drive the actuator back to a safe default position in the event of power failure. This is critical in emergency shutdown scenarios — especially for heating, cooling, or fire isolation systems.

Example: Some Belimo series of actuators include spring return functionality with a running time of just 75 seconds (90° rotation).

Belimo actuators offer full modulating control (0–10 VDC / 2–10 VDC or 4–20 mA) for precise flow regulation. This ensures smooth part-load performance in VAV, FCU, or chilled beam systems, preventing the wear-and-tear common with two-position (on/off) valves.

Some models even feature position feedback (DC 2–10 V) for real-time valve diagnostics and flow tuning

Belimo’s Energy Valve is a game-changer for hydronic systems. It combines a pressure-independent valve, actuator, and sensors to manage and optimise coil performance. It tracks ΔT (temperature differential), flow rate (l/min), and energy consumption (kWh) which are all visible through Belimo Cloud or BACnet/IP. These valves can even self-balance in real-time based on coil load.

Select Belimo actuators come rated to IP66 or IP67, meaning they’re fully protected against dust, high-pressure water jets, and even temporary submersion. Ideal for outdoor installs on rooftop plants, exposed pipework, or coastal environments.

Belimo actuators are plug-and-play with major building management systems via BACnet, Modbus RTU, Modbus TCP/IP, and Belimo’s proprietary MP-Bus. That means faster commissioning and less hassle integrating third-party controls.

All Belimo actuators feature brushless DC motors, sealed gearboxes, and overload protection, meaning no recalibration, zero lubrication, and no gearstrip from over-torque. This dramatically reduces service calls and long-term running costs.

Most models include a manual override lever or hex key drive for emergency operation or commissioning. This feature is often critical during staged handovers or mechanical testing when power is not yet live.

A Belimo energy valve combines a standard actuator with sensors for temperature, pressure, and flow. It regulates energy delivery by measuring delta T (temperature difference across the coil) and modulating valve position accordingly. This ensures efficient heating or cooling with no over-pumping.

Most Belimo actuators have a visual indicator on the housing that shows the current valve position. On digital models, you can also check the status via your BAS or through Belimo’s diagnostic tools (like the Belimo Assistant App using NFC).

Belimo actuators are designed to work with ball valves, butterfly valves, globe valves, and pressure-independent control valves. Their rotary actuators are ideal for high-torque applications, while linear models fit globe-style valves in chilled or hot water loops.

Read more

If you're an HVAC technician, BMS integrator, or building engineer having issues with a damper that won’t budge, valves acting up, or maybe you're still stuck adjusting things manually when they should run on their own. These problems usually boil down to one thing: how your system moves. That’s where a linear actuator comes in.

Linear actuators convert energy (from motors, air, or fluid) into straight-line motion. They move dampers, valves, arms, and panels without needing hands-on control. If a system needs to move something forward, backward, up, or down – precisely and repeatedly – it most likely uses a linear actuator.

This article will break down how they work, where they’re used, and why they’re critical in industries like HVAC, industrial automation, healthcare, and building controls.

A linear actuator generates linear motion (movement along a straight line) by converting rotational motion from a motor or hand crank into push/pull force. It works with a lead screw or ball screw system inside.

Here's the basic process for electric actuators:

In electric linear actuators, that motion is digitally controlled, perfect for tasks needing precise positioning, smooth operation, and tight tolerances. They’re widely used in building automation, medical equipment, robotics, and more.

Linear actuators are essential in systems where motion must be accurate and repeatable, like robotic surgical tools and solar panel tracking systems.

Actuators are everywhere once you start noticing. Let’s run through some real-world linear actuator uses examples:

Bottom line: If there’s a need to move something in a straight line with precision, actuators are probably involved.

Read More: What Are The Different Types of Actuators and Their Applications

Not all actuators are the same. Let’s look at the five main types of linear actuators used in HVAC, industrial automation, and beyond.

This is the most common in HVAC applications. An electric linear actuator uses an electric motor (AC or DC) to drive a lead screw, converting rotational motion into straight-line movement. Ideal for precise control with minimal maintenance.

These use pressurised incompressible hydraulic fluid to move a piston inside a cylinder. They offer high force output, great for heavy-duty industrial applications.

These run on compressed air, offering fast movement but less precise control compared to electric actuators. They're cost-effective and often used where speed matters more than pinpoint accuracy.

This includes devices like rack-and-pinion systems, lead screw drives, and belt drives that convert rotary to linear motion through mechanical means alone.

The most precise of the bunch. These use piezoelectric materials that expand or contract with voltage, generating ultra-fine linear motion.

Used in: High-end lab or imaging devices

The main job of an actuator is to convert energy into motion, specifically, to move or control a mechanism like a valve or damper. In HVAC, it's the bridge between electronic control signals and mechanical action.

Linear motion is everywhere: electric recliners, printers, automatic windows, and even adjustable hospital beds. In HVAC, linear actuators open or close dampers, regulate valve positions, and help maintain building comfort.

Linear actuators are used where movement in a straight line is needed, like opening valves or pushing something along a track. Rotary actuators, on the other hand, provide rotational motion and are used in applications like turning wheels, rotating antennae, or swivelling robotic joints.

Electric linear actuators are known for precise positioning and repeatability. Because they use motors and encoders, they’re perfect for tasks that need controlled, consistent movement, ideal for automation and building management systems.

Electric actuators offer low maintenance, clean operation, and better precision. Pneumatic actuators may be cheaper upfront but need ongoing compressed air supply. Hydraulic actuators offer power but come with leakage and servicing issues. Electric systems are more efficient for HVAC and automation.

If your HVAC system needs precise, reliable valve control, electric linear actuators are your best bet. But if your project requires high force or speed, or you're working in a highly automated industrial environment, other types might be a better fit.

Still unsure which actuator suits your needs?

Check out our catalogue at Controls Traders. We've got over 40 years of combined experience in HVAC controls and industrial automation, which has helped us stock the best. Our team can also help you pick the right actuator, whether you're looking for Honeywell, Johnson Controls, Belimo, Siemens, Schneider Electric, or other trusted global brands.

You can shop by brand, shop by product, send us a message or call us at 1300 740 140 for enquiries.

Read more

.jpg)

You’re probably responsible for keeping building systems running, whether it’s a multi-storey HVAC network, a water treatment plant, or a site with strict automation requirements. And when something as small as a valve actuator fails, everything downstream grinds to a halt.

So, what does a valve actuator do? It's a mechanical or electromechanical component that moves a valve: opening, closing, or adjusting it automatically to control the flow of liquid or gas. Whether powered by air, electricity, or hydraulic pressure, valve actuators enable hands-free, precise flow control in modern systems.

For South Australian HVAC professionals, control engineers, and facilities managers, understanding actuator valves is essential to preventing downtime and keeping your systems safe, efficient, and responsive.

In a nutshell: we use valve actuators to automate the movement of a valve (either opening, closing, or modulating it) without manual effort. But that’s just scratching the surface.

A valve actuator’s purpose is to control the movement of a valve’s internal components to start, stop, or regulate the flow of gas or liquid in a system. Without it, automated control of HVAC, water, or fuel systems just isn’t possible.

Let's say you have a commercial air conditioning system in an Adelaide office building. You don’t want someone climbing into the ceiling to twist a valve every time the temperature changes.

Instead, an actuator receives a signal from the building’s control system and adjusts the airflow instantly, whether it comes from a programmable logic controller (PLC), building management system (BMS), or local thermostat.

A valve actuator works by converting a control signal, usually electric, pneumatic (compressed air), or hydraulic pressure, into mechanical movement. This movement turns or lifts the valve stem, opening or closing the valve.

There are two core motion types:

The actuator receives input from a control system and applies force to adjust valve position. Some actuators include a feedback loop so the system knows the exact valve position at all times, key for precise control in HVAC, fluid power, and industrial settings.

In industrial, HVAC, and building automation settings, here’s what an actuator enables:

Valve actuators allow remote or programmatic control of valve positions via a control system (e.g. BMS or DDC controller). That means no need to operate the valve on-site physically.

In an HVAC system serving a multi-storey commercial building, you might have zone control valves for chilled water distribution. A Belimo electric actuator connected to the BMS can:

Common actuator types include electric (modulating or 2-position) and Pneumatic (for legacy or high-speed systems).

Valve actuators allow instant shut-off or redirection of fluid/gas flow during emergencies, without relying on human intervention. This is especially vital in systems handling high-pressure steam, toxic gases, or flammable fluids.

Let’s say you’re managing a boiler room or chilled water plant. In the event of a power failure or fire:

Example: A Johnson Controls VA-7150 actuator paired with a globe valve in a hot water loop. When the fire alarm is triggered, it automatically closes to prevent overheating or pressure spikes.

In large HVAC or water systems, energy efficiency comes down to flow control. Valve actuators are also used for optimising energy use with flow precision. The actuator’s role is to regulate flow exactly as needed, avoiding over-pumping, pressure imbalances, or thermal drift.

Modulating actuators receive continuous feedback (via 0–10V or 4–20mA signals) and adjust the valve position accordingly.

This ensures variable flow based on demand, not a static open/close state.

In a commercial air handling unit (AHU), equipping your chilled water valve with an electric actuator can:

Bonus: Many high-end actuators integrate BACnet or Modbus for direct communication with smart controllers, helping to streamline setup and ongoing optimisation.

Manual valves are subject to operator error, wear, and variation. But a high-quality actuator ensures that:

Some facilities in high-demand zones may run cooling towers or process loops 24/7. A Siemens GCA actuator installed on a 2-way valve can:

Deliver ±1% positioning accuracy for tight fluid control, which is ideal for pharmaceutical labs, hospitals, or clean rooms.

The actuator moves the valve stem to open or close the valve, controlling the flow of a liquid or gas through a system. It responds to signals from control systems to ensure precise and repeatable operations.

Look for inconsistent valve movement, loss of pressure (in pneumatic systems), strange noises, or slow response times. If a control valve actuator isn’t reacting properly, it may need recalibration or replacement.

It depends. Electric actuators provide quiet and accurate control, particularly for indoor systems. Pneumatic actuators are more durable in extreme environments and are generally cheaper to maintain where compressed air is available.

In many cases, yes, especially if the valve body is in good shape. Make sure the replacement actuator is compatible in terms of torque, motion type, and mounting interface.

Depending on the system design, a failed actuator could leave a valve stuck open or closed. In critical systems, this can halt operations or trigger emergency shutdowns. Spring-return actuators are often used to return to a safe state in the event of failure. Shop a replacement valve actuator here.

Need help retrofitting your HVAC system or matching an actuator to your valve? Control Traders supplies Honeywell, Belimo, Danfoss, Siemens, Schneider Electric, Johnson Controls, and more, with stock on hand and fast delivery across South Australia. Shop by brand or browse actuator valves by product name.

Do you prefer to talk it through? Our team has 40+ years of in-house experience in HVAC instruments. Call 1300 740 140 or send a message. Let's help you spec it right the first time.

Read moreSign up by email to receive inspiration, product updates and special offers from our team.

ACS Supplies

ACS Supplies

Welcome to our website. If you continue to browse and use this website, you are agreeing to comply with and be bound by the following terms and conditions of use, which together with our privacy policy govern Controls Traders Pty Ltd’s relationship with you in relation to this website. If you disagree with any part of these terms and conditions, please do not use our website.

The term ‘Controls Traders Pty Ltd’ or ‘us’ or ‘we’ refers to the owner of the website whose registered office is 40 Stepney Street, STEPNEY SA 5069. Our ABN is 21 610 375 365. The term ‘you’ refers to the user or viewer of our website.

The use of this website is subject to the following terms of use:

This privacy policy sets out how we uses and protects any information that you give us when you use this website.

We are committed to ensuring that your privacy is protected. Should we ask you to provide certain information by which you can be identified when using this website, then you can be assured that it will only be used in accordance with this privacy statement.

We may change this policy from time to time by updating this page. You should check this page from time to time to ensure that you are happy with any changes.

What we collect

We may collect the following information:

What we do with the information we gather

We require this information to understand your needs and provide you with a better service, and in particular for the following reasons:

Security

We are committed to ensuring that your information is secure. In order to prevent unauthorised access or disclosure, we have put in place suitable physical, electronic and managerial procedures to safeguard and secure the information we collect online.

How we use cookies

A cookie is a small file which asks permission to be placed on your computer's hard drive. Once you agree, the file is added and the cookie helps analyse web traffic or lets you know when you visit a particular site. Cookies allow web applications to respond to you as an individual. The web application can tailor its operations to your needs, likes and dislikes by gathering and remembering information about your preferences.

We use traffic log cookies to identify which pages are being used. This helps us analyse data about webpage traffic and improve our website in order to tailor it to customer needs. We only use this information for statistical analysis purposes and then the data is removed from the system.

Overall, cookies help us provide you with a better website by enabling us to monitor which pages you find useful and which you do not. A cookie in no way gives us access to your computer or any information about you, other than the data you choose to share with us.

You can choose to accept or decline cookies. Most web browsers automatically accept cookies, but you can usually modify your browser setting to decline cookies if you prefer. This may prevent you from taking full advantage of the website.

Links to other websites

Our website may contain links to other websites of interest. However, once you have used these links to leave our site, you should note that we do not have any control over that other website. Therefore, we cannot be responsible for the protection and privacy of any information which you provide whilst visiting such sites and such sites are not governed by this privacy statement. You should exercise caution and look at the privacy statement applicable to the website in question.

Controlling your personal information

You may choose to restrict the collection or use of your personal information in the following ways:

We will not sell, distribute or lease your personal information to third parties unless we have your permission or are required by law to do so. We may use your personal information to send you promotional information about third parties which we think you may find interesting if you tell us that you wish this to happen.

If you believe that any information we are holding on you is incorrect or incomplete, please write to or email us as soon as possible at the above address. We will promptly correct any information found to be incorrect.